Greener' way to assemble materials for solar applications

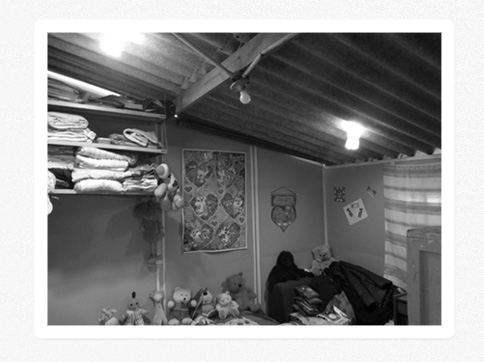

A surfactant template guides the self-assembly of functional polymer structures in an aqueous solution.

Credit: Image credit: Oak Ridge National Laboratory, U.S. Dept. of Energy; image by Youngkyu Han and Renee Manning.

The efficiency of solar cells depends on precise engineering of polymers that assemble into films 1,000 times thinner than a human hair.

Today, formation of that polymer assembly requires solvents that can harm the environment, but scientists at the Department of Energy's Oak Ridge National Laboratory have found a "greener" way to control the assembly of photovoltaic polymers in water using a surfactant-- a detergent-like molecule--as a template. Their findings are reported in Nanoscale, a journal of the Royal Society of Chemistry.

"Self-assembly of polymers using surfactants provides huge potential in fabricating nanostructures with molecular-level controllability," said senior author Changwoo Do, a researcher at ORNL's Spallation Neutron Source (SNS).

The researchers used three DOE Office of Science User Facilities--the Center for Nanophase Materials Sciences (CNMS) and SNS at ORNL and the Advanced Photon Source (APS) at Argonne National Laboratory--to synthesize and characterize the polymers.

"Scattering of neutrons and X-rays is a perfect method to investigate these structures," said Do.

The study demonstrates the value of tracking molecular dynamics with both neutrons and optical probes.

"We would like to create very specific polymer stacking in solution and translate that into thin films where flawless, defect-free polymer assemblies would enable fast transport of electric charges for photovoltaic applications," said Ilia Ivanov, a researcher at CNMS and a corresponding author with Do. "We demonstrated that this can be accomplished through understanding of kinetic and thermodynamic mechanisms controlling the polymer aggregation."

The accomplishment creates molecular building blocks for the design of optoelectronic and sensory materials. It entailed design of a semiconducting polymer with a hydrophobic ("water-fearing") backbone and hydrophilic ("water-loving") side chains. The water-soluble side-chains could allow "green" processing if the effort produced a polymer that could self-assemble into an organic photovoltaic material. The researchers added the polymer to an aqueous solution containing a surfactant molecule that also has hydrophobic and hydrophilic ends. Depending on temperature and concentration, the surfactant self-assembles into different templates that guide the polymer to pack into different nanoscale shapes--hexagons, spherical micelles and sheets.

In the semiconducting polymer, atoms are organized to share electrons easily. The work provides insight into the different structural phases of the polymer system and the growth of assemblies of repeating shapes to form functional crystals. These crystals form the basis of the photovoltaic thin films that provide power in environments as demanding as deserts and outer space.

"Rationally encoding molecular interactions to rule the molecular geometry and inter-molecular packing order in a solution of conjugated polymers is long desired in optoelectronics and nanotechnology," said the paper's first author, postdoctoral fellow Jiahua Zhu. "The development is essentially hindered by the difficulty of in situ characterization."

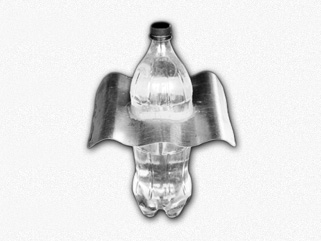

In situ, or "on site," measurements are taken while a phenomenon (such as a change in molecular morphology) is occurring. They contrast with measurements taken after isolating the material from the system where the phenomenon was seen or changing the test conditions under which the phenomenon was first observed. The team developed a test chamber that allows them to use optical probes while changes occur.

Neutrons can probe structures in solutions

Expertise and equipment at SNS, which provides the most intense pulsed neutron beams in the world, made it possible to discover that a functional photovoltaic polymer could self-assemble in an environmentally benign solvent. The efficacy of the neutron scattering was enhanced, in turn, by a technique called selective deuteration, in which specific hydrogen atoms in the polymers are replaced by heavier atoms of deuterium--which has the effect of heightening contrasts in the structure. CNMS has a specialty in the latter technique.

"We needed to be able to see what's happening to these molecules as they evolve in time from some solution state to some solid state," author Bobby Sumpter of CNMS said. "This is very difficult to do, but for molecules like polymers and biomolecules, neutrons are some of the best probes you can imagine." The information they provide guides design of advanced materials.

By combining expertise in topics including neutron scattering, high-throughput data analysis, theory, modeling and simulation, the scientists developed a test chamber for monitoring phase transitions as they happened. It tracks molecules under conditions of changing temperature, pressure, humidity, light, solvent composition and the like, allowing researchers to assess how working materials change over time and aiding efforts to improve their performance.

Scientists place a sample in the chamber and transport it to different instruments for measurements. The chamber has a transparent face to allow entry of laser beams to probe materials. Probing modes--including photons, electrical charge, magnetic spin and calculations aided by high-performance computing--can operate simultaneously to characterize matter under a broad range of conditions. The chamber is designed to make it possible, in the future, to use neutrons and X-rays as additional and complementary probes.

"Incorporation of in situ techniques brings information on kinetic and thermodynamic aspects of materials transformations in solutions and thin films in which structure is measured simultaneously with their changing optoelectronic functionality," Ivanov said. "It also opens an opportunity to study fully assembled photovoltaic cells as well as metastable structures, which may lead to unique features of future functional materials."

Whereas the current study examined phase transitions (i.e., metastable states and chemical reactions) at increasing temperatures, the next in situ diagnostics will characterize them at high pressure. Moreover, the researchers will implement neural networks to analyze complex nonlinear processes with multiple feedbacks.

The title of the Nanoscale paper is "Controlling molecular ordering in solution-state conjugated polymers."

Source by:

http://www.sciencedaily.com/releases/2015/10/151005163040.htm